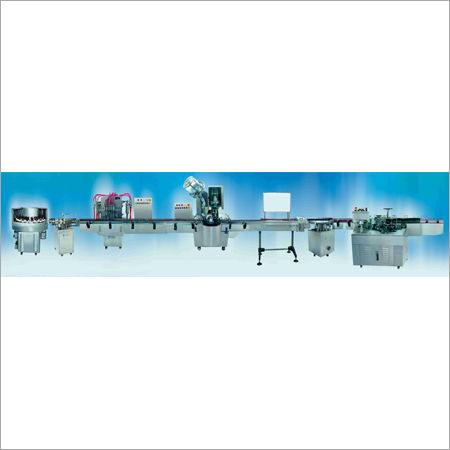

External Ampoule Cleaning Machine

2000000 INR/Unit

Product Details:

- Features Heavy Duty

- Usage & Applications Pharma Plant & Machinery

- Noise Level Low db

- Type Ampoule Cleaning Machine

- Material Stainless Steel

- Computerized Yes

- Control Mode Automatic

- Click to View more

X

External Ampoule Cleaning Machine Price And Quantity

- 2000000 INR/Unit

- 1 Unit

External Ampoule Cleaning Machine Product Specifications

- Silver

- Pharma Plant & Machinery

- Heavy Duty

- Yes

- Low db

- Stainless Steel

- Automatic

- Ampoule Cleaning Machine

External Ampoule Cleaning Machine Trade Information

- 50 Unit Per Year

- 8 Week

- All India

Product Description

Creating a striking mark in the industry, we have earned the name of being a highly reliable manufacturer and supplier of External Ampoule Cleaning Machine. It is designed especially for adjustable powerful washing nozzles. We manufacture this machine under the firm guidance of expert supervisors using high quality materials and components. External Ampoule Cleaning Machine performs better in labeling machines and downstream inspection. Acrylic cover and Stainless steel surrounds the machine along with safety interlock system.

Features:

- PLC control system

- Built in recycling unit

- Has touch screen for user friendly operation

External Ampoule Cleaning Machine

Features:

- It has touch screen user friendly operation.

- It consist PLC control system.

- Designed especially for adjustable powerful washing nozzles

- Performs better in labeling machines and downstream inspection.

- Separate pipes in the jetting stations washing medias fed through

- Recycling unit is in-built.

- Cut out switch with low pressure is provided for washing Medias.

- Optional pre-washing station for highly contaminated ampoules.

- The main machine and in-feed conveyor contains Separate A.C frequency.

- Acrylic cover and Stainless steel surrounds the machine along with safety interlock system.

- Change overtime does not take time.

- All machines parts that interacts water is made of pharma graded nylocaste material and stainless steel 31 6 quality.

- The machine is placed on castor wheels for easy movement.

Precision Cleaning for Ampoules

Engineered to deliver thorough external cleaning of ampoules, this machine supports pharmaceutical production by maintaining sterile conditions. Its automated, computerized control streamlines operations, reducing human error and improving consistency. With low noise emission and robust stainless steel construction, it assures reliability for high-volume usage.

Advanced Features for Pharma Industry

The ampoule cleaning machine stands out with its heavy-duty build, automatic control mode, and noise-reduction architecture. These features contribute significantly to ensuring a controlled environment and seamless operation within the demanding settings of a pharma plant.

FAQ's of External Ampoule Cleaning Machine:

Q: How does the External Ampoule Cleaning Machine operate in an automatic mode?

A: The machine uses advanced computerized controls to automate the ampoule cleaning process, reducing manual intervention and efficiently removing contaminants from pharmaceutical containers.Q: What materials are used in the construction of this ampoule cleaning machine?

A: It is constructed using high-grade stainless steel, which ensures durability, corrosion resistance, and maintains hygiene standards required in pharma production environments.Q: When should a pharma facility consider using this ampoule cleaning machine?

A: Pharmaceutical facilities should utilize this machine during batch production cycles where external ampoule cleanliness is crucial to prevent contamination and maintain product quality.Q: Where is the External Ampoule Cleaning Machine primarily used?

A: This machine is predominantly employed in pharmaceutical plants and machinery setups across India, by exporters, manufacturers, suppliers, and traders catering to the pharma sector.Q: What is the process involved in cleaning ampoules with this equipment?

A: Ampoules are fed into the machine, which automatically executes cleaning cycles using programmed mechanisms to ensure uniform removal of any external impurities without manual handling.Q: How does this machine benefit pharmaceutical companies?

A: It delivers reliable, low-noise, high-speed cleaning with minimal human intervention, significantly enhancing productivity, ensuring product safety, and supporting compliance with regulatory standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free