Automatic Tablet Coating Machine

300000 INR/Unit

Product Details:

- Type Film Coating Machines

- Computerized Yes

- Control Mode Automatic

- Voltage 415 Watt (w)

- Color S. S. matt finish

- Warranty 1yr

- Click to View more

X

Automatic Tablet Coating Machine Price And Quantity

- 1 Unit

- 300000 INR/Unit

Automatic Tablet Coating Machine Product Specifications

- 1yr

- Film Coating Machines

- S. S. matt finish

- Automatic

- Yes

- 415 Watt (w)

Automatic Tablet Coating Machine Trade Information

- KOLKATA

- 50 Unit Per Year

- 8 Week

- SEA WORTHY WOODEN BOXES

- All India

Product Description

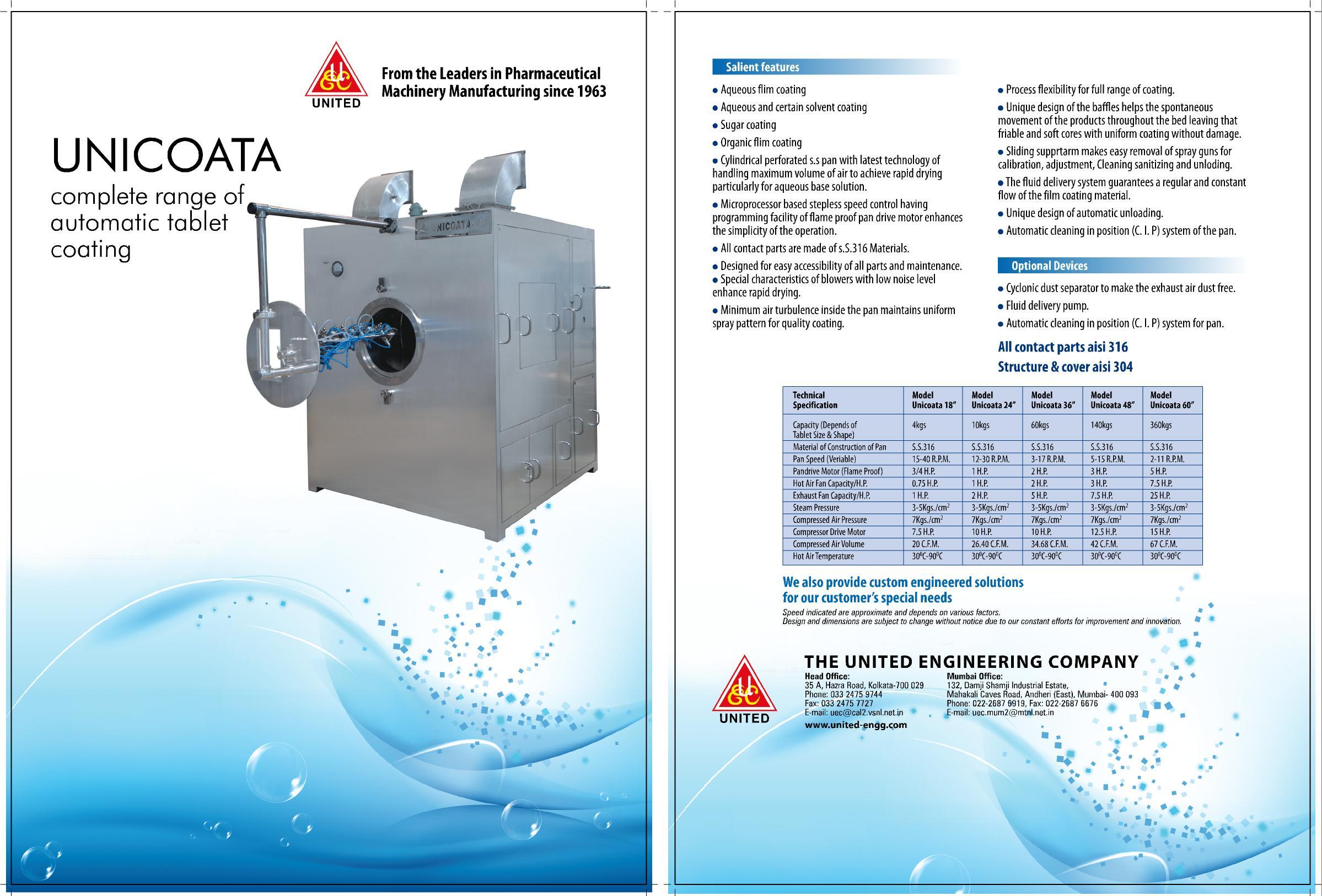

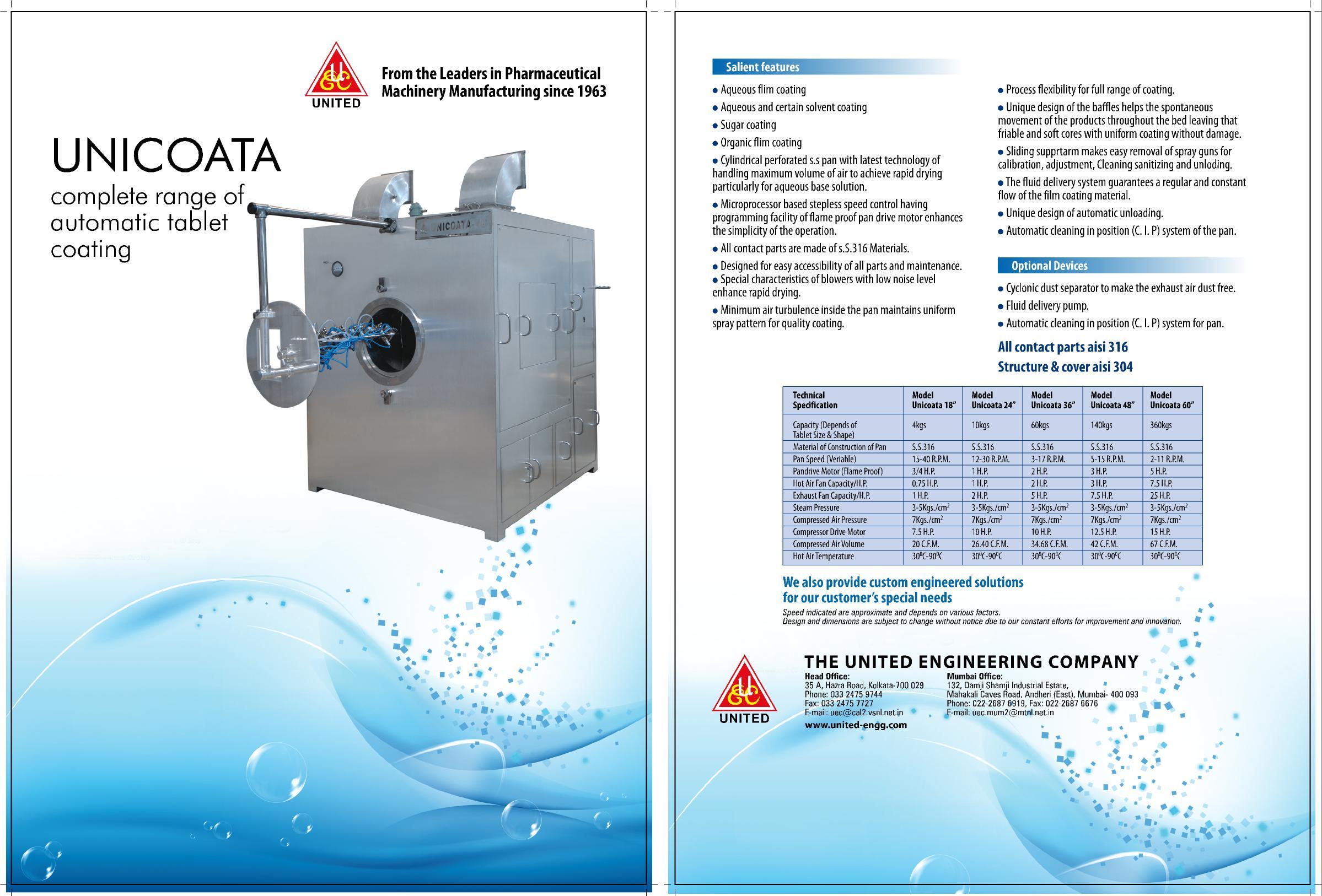

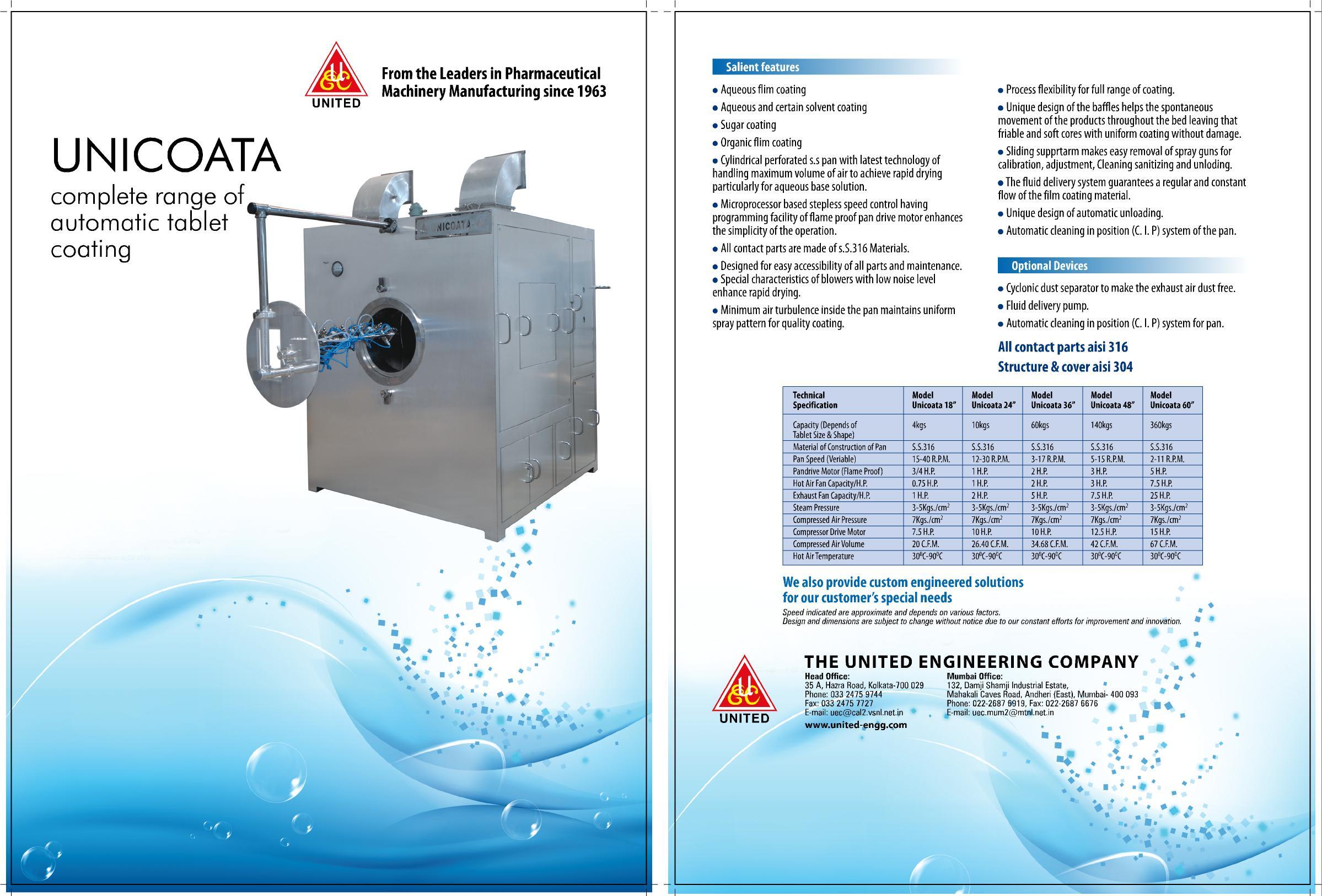

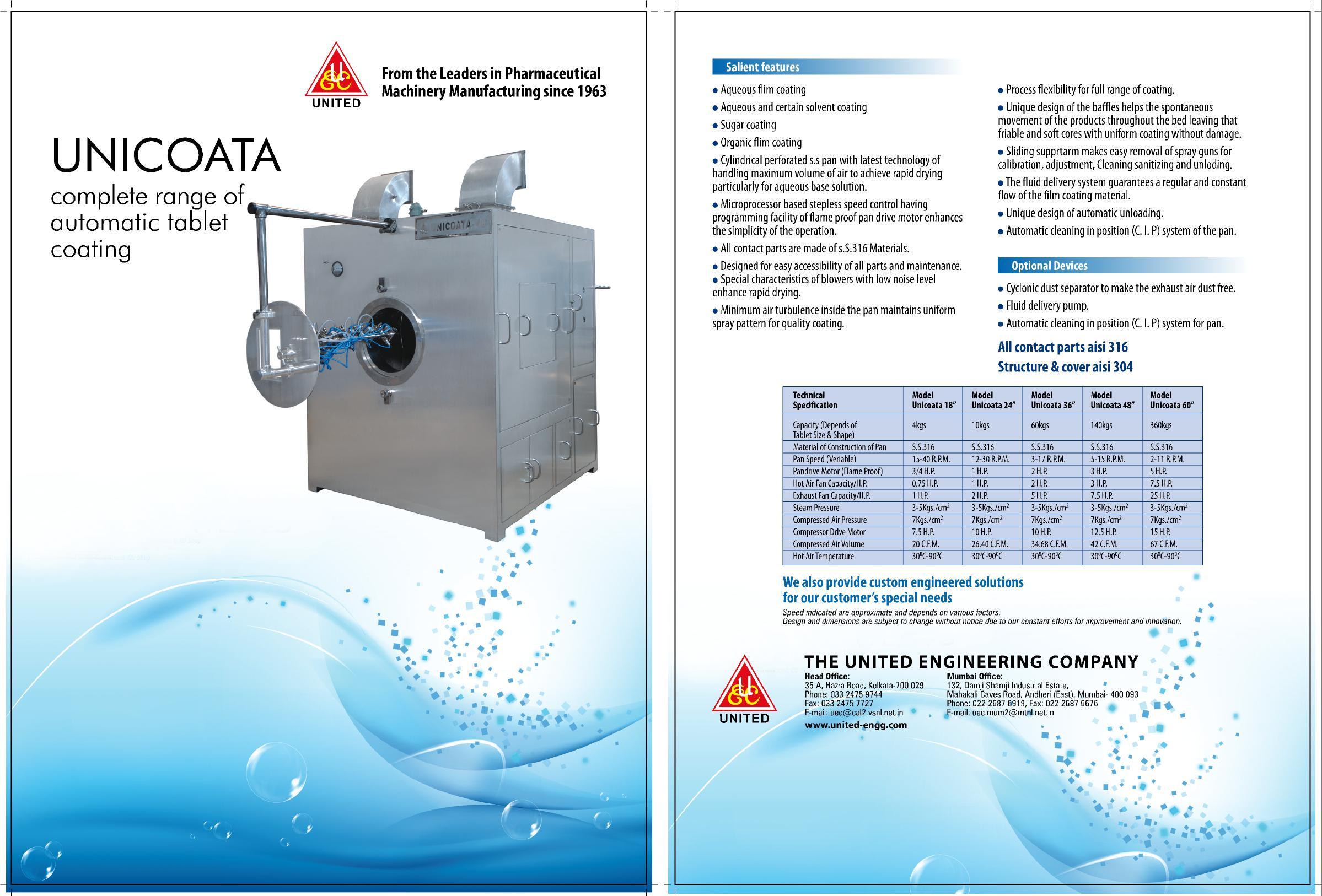

We are a well-established firm that has made its presence in the industry, by manufacturing and supplying Automatic Table Coating Machine. The machine has cylindrical perforated S.S. pan with latest technology of handling air to achieve rapid drying particularly for aqueous based solution. To manufacture this machine, our diligent workforce uses quality grade mild steel and steel alloys. Minimum air turbulence inside pan maintains uniform spraying pattern for quality coating. We offer Automatic Table Coating Machine at cost effective prices.

Features:

- Optional cyclonic dust separator

- PLC based control with HMI and SCADA software

- Cylindrical perforated S.S. pan

Features

- C.I.P and unloading system is automatic.

- Cylindrical perforated S.S. pan with latest technology of handling maximizes the air to achieve rapid drying particularly for aqueous based solution.

- Rapid drying is enhanced through Blower with less noise level.

- Minimum air turbulence inside pan maintains uniform spraying pattern for quality coating.

- flexible with full range of coating.

- PLC based control with HMI and SCADA software.

- It has an Optional cyclonic dust separator for free pollution exhaust system.

- All contact parts are of stainless steel (316 quality).

- Optimum coating results with simple operation.

Advanced Film Coating Technology

Experience superior tablet coating with this automated machine utilizing state-of-the-art film coating methods. Its computerized controls enable accurate parameter settings for optimal results in pharmaceutical environments. The stainless steel matt finish ensures operational safety and maintains compliance with industry hygiene standards, making it suitable for large-scale production.

User-Friendly and Efficient Operation

The automatic control system simplifies usage, allowing operators to manage coating processes with minimal training. Enhanced efficiency leads to higher throughput and consistent tablet quality. Exported worldwide from India, the machine meets international fabrication standards and is used by manufacturers, suppliers, and traders for reliable production.

FAQ's of Automatic Tablet Coating Machine:

Q: How does the automatic tablet coating machine operate?

A: The machine uses a computerized system to control all aspects of the film coating process. Operators simply set the desired parameters, and the automatic control mode manages temperature, spray rate, and drum rotation, ensuring even and consistent tablet coating.Q: What benefits does the stainless steel matt finish provide?

A: The S.S. matt finish offers excellent durability and hygiene. It is easy to clean, resistant to corrosion, and ideal for maintaining product integrity during pharmaceutical production.Q: When is this film coating machine typically used in manufacturing?

A: This machine is typically used during the final stage of tablet production, where uniform film coating is required to protect tablets, control release of ingredients, or enhance their appearance.Q: Where is this automatic tablet coating machine manufactured and exported from?

A: The machine is manufactured and exported from India, serving the needs of international clients in pharmaceutical sectors as a reliable product from an established exporter, manufacturer, supplier, and trader.Q: What is the main process involved in tablet film coating with this machine?

A: The process involves loading tablets into the coating drum, setting computerized parameters, and starting automatic operation. The machine uniformly sprays coating solution, dries the tablets, and delivers a finished batch with consistent quality.Q: How does the automatic control mode enhance the machine's usage?

A: Automatic control mode allows precise adjustments to coating parameters, ensuring repeatability and minimizing operator errors. It increases safety and reduces manual intervention, making the process more efficient.Q: What warranty coverage is included with the machine?

A: The automatic tablet coating machine comes with a one-year warranty, which covers manufacturing defects and ensures prompt assistance for troubleshooting or repairs during the initial period of use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free