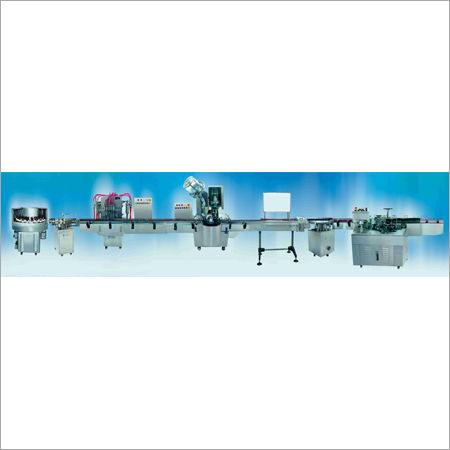

Automatic Rotary Screw Capping Machine

Product Details:

- Usage & Applications Pharma Plant & Machinery

- Features Heavy Duty

- Noise Level Low db

- Type Screw Capping Machine

- Material Stainless Steel

- Computerized Yes

- Control Mode Automatic

- Click to View more

Automatic Rotary Screw Capping Machine Price And Quantity

- 550000 INR/Unit

- 1 Unit

Automatic Rotary Screw Capping Machine Product Specifications

- Low db

- Screw Capping Machine

- Heavy Duty

- Silver

- Yes

- Stainless Steel

- Automatic

- Pharma Plant & Machinery

Automatic Rotary Screw Capping Machine Trade Information

- 50 Unit Per Year

- 8 Week

- All India

Product Description

Widely known as a trusted company, we are engrossed in manufacturing, exporting and supplying premium quality Automatic Rotary Screw Capping Machine. The offered machine is widely used in pharmaceutical, chemical, cosmetic, food processing and beverage industries for sealing the caps of bottles and containers. The provided machine is manufactured using quality approved components and advanced technology under the supervision of our diligent proficient keeping in mind international quality standards. To meet the varied requirement of our clients, we offer this Automatic Rotary Screw Capping Machine in different specification at most affordable prices.

Features:

-

Corrosion resistance coating body

-

Long service life and low power consumption

-

Easy to operate

- Less maintenance and easy installation

Advanced Automation for Reliable Capping

This rotary screw capping machine features automatic controls that streamline the capping process with minimal manual intervention. Its computerized system guarantees consistent cap application, reducing human error and increasing throughput. Designed specifically for pharma applications, it meets rigorous safety and operational standards.

Durable Stainless Steel Construction

Built with high-quality stainless steel, this screw capping machine offers exceptional resistance to corrosion and wear, making it ideal for demanding pharmaceutical environments. The silver finish not only enhances its appearance but also simplifies cleaning and maintenance.

Export Quality and Nationwide Support

As a leading exporter, manufacturer, supplier, and trader in India, we provide comprehensive support and service for our rotary screw capping machines. Our network ensures timely delivery, installation, and ongoing assistance, catering to the diverse needs of pharma plants across the country.

FAQ's of Automatic Rotary Screw Capping Machine:

Q: How does the automatic rotary screw capping machine operate in a pharmaceutical plant?

A: The machine is equipped with computerized automatic controls that manage the entire capping process. Containers move through the rotary system, and screw caps are accurately applied with minimal manual intervention, optimizing efficiency and reducing labor.Q: What are the main benefits of using a heavy-duty screw capping machine?

A: Its heavy-duty construction guarantees longevity and stable operation, even in high-volume production environments. Benefits include enhanced productivity, consistent cap application, low maintenance requirements, and reliable performance in pharmaceutical settings.Q: Where can this rotary screw capping machine be installed and used?

A: This machine is primarily designed for installation in pharmaceutical plants and machinery units across India. It is extensively deployed in production lines for bottling and packaging operations where automated screw capping is required.Q: When is computerized control especially advantageous in the capping process?

A: Computerized control is particularly beneficial when high precision and consistency are needed, such as in pharma manufacturing. It helps maintain quality standards, reduce errors, and minimize downtime, especially during large-scale operations.Q: What is the typical process for installing and commissioning this machine?

A: Once delivered, installation is carried out by qualified technicians provided by our support network. The machine is integrated into existing production lines, configured for container sizes, and tested for accuracy and efficiency before commissioning.Q: How does the low noise level benefit pharma plant operations?

A: The machine operates at a low decibel level, minimizing auditory disruptions in the workspace. This fosters a more comfortable environment for workers and helps comply with occupational health standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+